Topology optimization and 3D printing of a crank

Author:

Paul-Adrien TAVEAU, Christophe ROUA

Abstract:

As COGIT Composites bought a 3D printer, the company has demonstrated its ability to use topology optimization and additive manufacturing by designing a crank and by printing it by the fused deposition modeling method. The use of a technical polymer proved to be decisive in meeting the objectives of lightness, 3D geometry and stiffness.

Keywords: Topology optimization, additive manufacturing, engineering, conception, structural calculation, thermoplastics, 3D printing

Content:

While a crank was broken on one of our machines, COGIT Composites developed a new part to replace it.

The challenge was to:

– Keep the kinematics functions of the original part

– Design a robust equipment

– Reduce the mass by 30%

– Keep a compact design

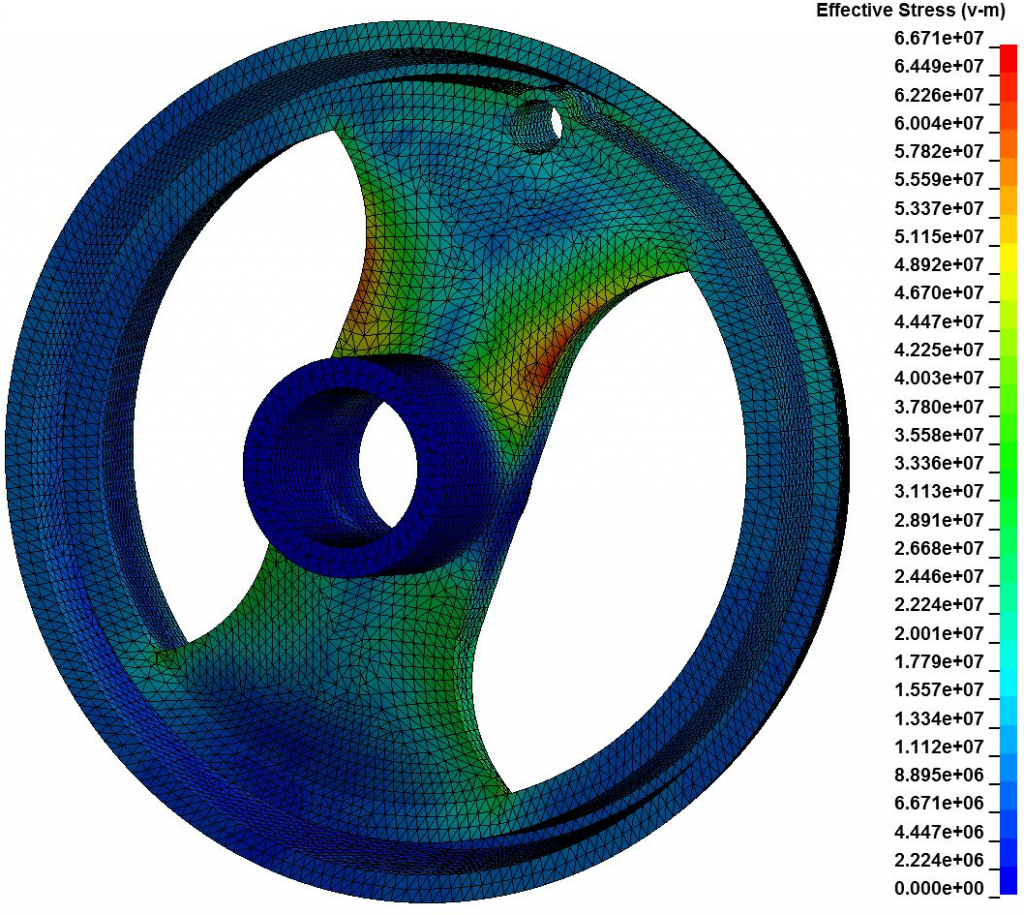

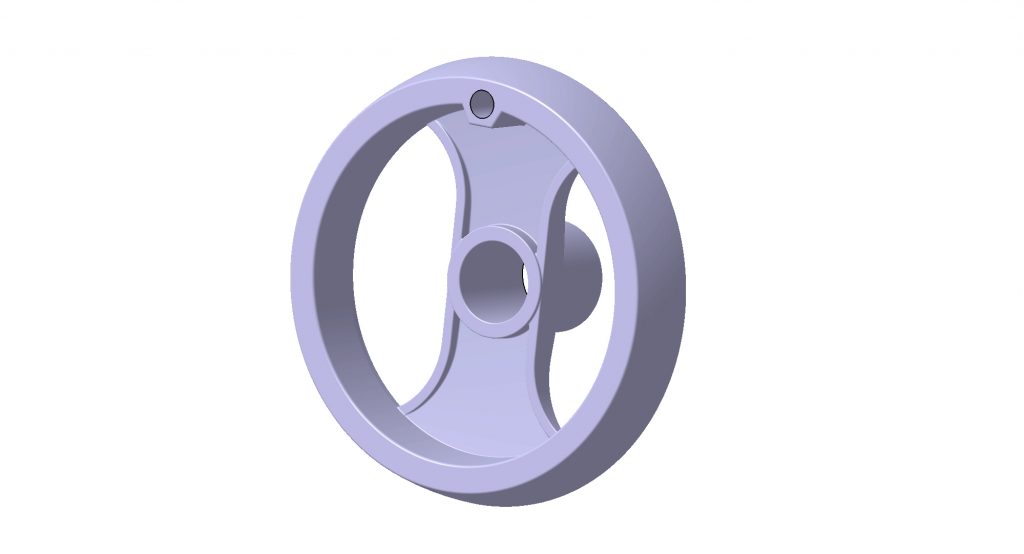

COGIT Composites started by redacting the specification. Then, the digital model of the original crank was reconstituted using a CAD (Computer Aided Design) software. Structural calculation software was used to characterize the mechanical strength of the original crank to serve as a basis for comparison.

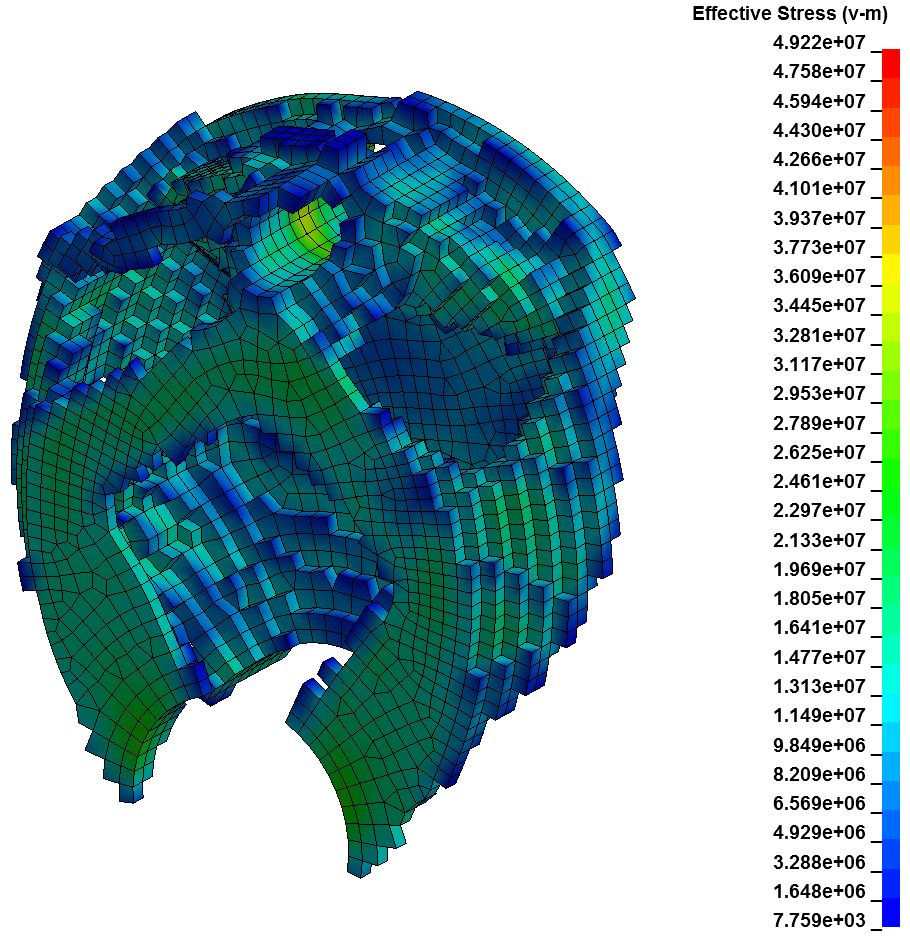

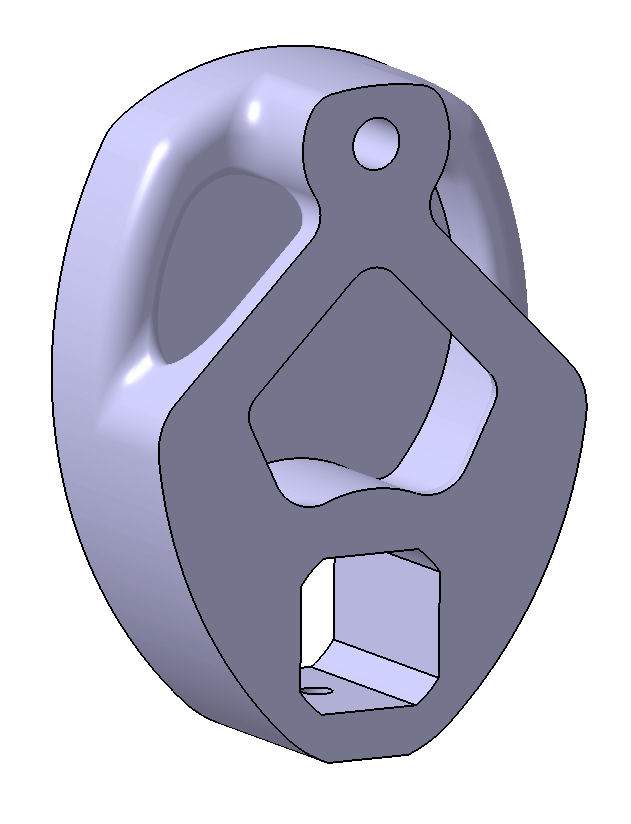

The new crank has been designed thanks to the results of a topology optimization software and was validated by structural calculation.

The crank was manufactured by the FDM (Fused Deposition Modeling) method. This method allow to create a piece, layer by layer, by depositing a molten filament over a plate. A technical polymer has been selected to guarantee the robustness of the part.

The optimized crank exceeds the specification by allowing a mass reduction of 45% while maintaining the mechanical properties of the existing crank.

Conclusions:

In less than three months, COGIT Composites has successfully designed, justified by calculation, produce and assemble a piece topologically optimized and additively manufactured. The objectives of lightness and rigidity of the system have been achieved.

Materials:

Technical polymers

Software:

Catia V5, topology optimization software, structural calculation software