Laboratory dedicated to process

Our laboratory specialises in the mastery of composite processes. Two industrial processes are characterised, studied and optimised :

1. Stamping of thermoplastics composites (pratical work),

2. PEKK composites overmoulding,

3. Liquid Composites Molding (RTM, Infusion and derivatives),

4. Additive Manufacturing,

5. Static testing

1.Thermoplastic Composite Stamping :

We are also equipped with a specialisedlaboratory press for stamping hermoplastic composites (PEEK, PPS, PA, PEI...)

This tool enables us to :

- refine the technical feasibility of part from a pre-consolidated plate

- determine the correct parameters fro the stamping cycle (temperature, pressure, ...)

- develop tooling in the pre-production phase

2.PEKK composite overmoulding :

Since 2017, COGIT Composites has been functionalising high-performance thermoplastic composites parts, in particular based on PEEK and PEKK.

Here, we present two PEEK carbon parts over-moulded with 30% carbon-reinforced PEKK plastic :

- a one-shot stamped and over-moulded plate, including ribs and metal inserts

- a pre-stamped then over-moulded frame, including edging, reinforcements and a ball joint inclusion (Arche 4.2 project -Stelia)

COGIT Composites has the means to characterise the inteface between the composites and the injected polymer.

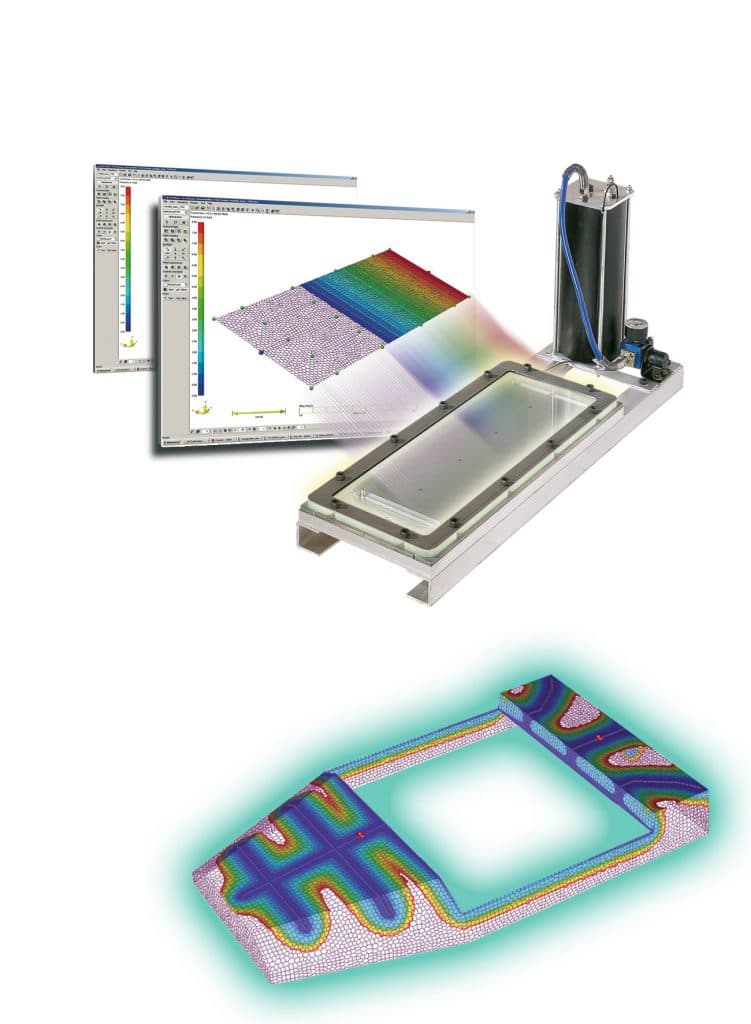

3.Liquid Composite Molding process :

For several years now, the RTM ans Infusion manufacturing processes have been used to characterise permeabilityin the plane and in the thickness.

This enables us to feed injection simulation codes. We produce standardised RTM test specimens for the mechanical characterisation of these composites. We are able to produce ârts and validate heavy RTM tools.

4.additive manufacturing :

COGIT Additive Manufacturing is the new pole of expertise of COGIT Composites. Thanks to its experience in thermoplastic composite materials, our team develops :

- a large-scale 3D printer,

- a pellet extruder, both for high performance materials.

To go further, you can find our products on our website cogit.am.

Manufacturing simulation

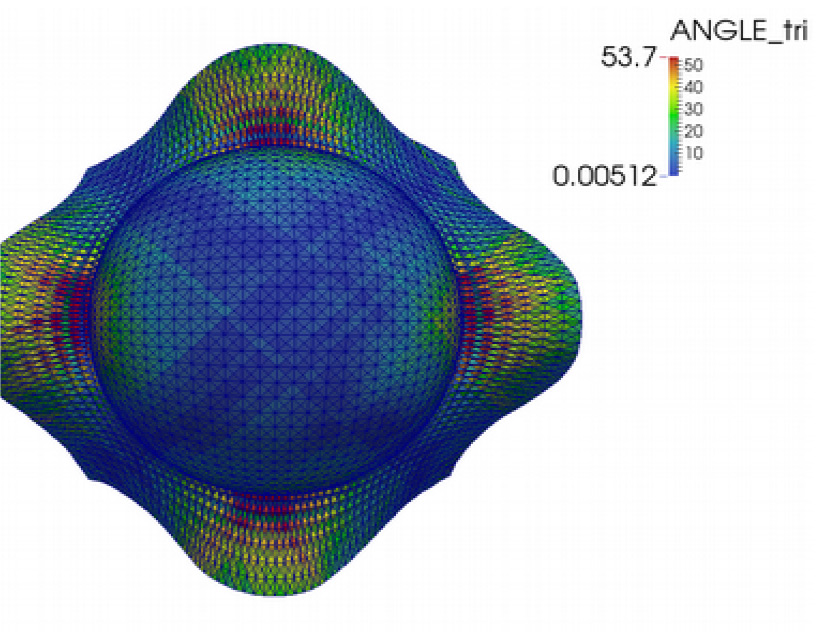

Rare in Europe, COGIT Composites has got means and capabilities to improve RTM and infusion manufacturing. Based on our internal laboratory, we can simulate the flow front of resin.

Our tools and skills enable us to :

- simulate several strategies so as to choose vent and port location and other parameters.

- limit industrial risks of new project or improve already in place manufacturing