CAD Design

The CAD Design concerns :

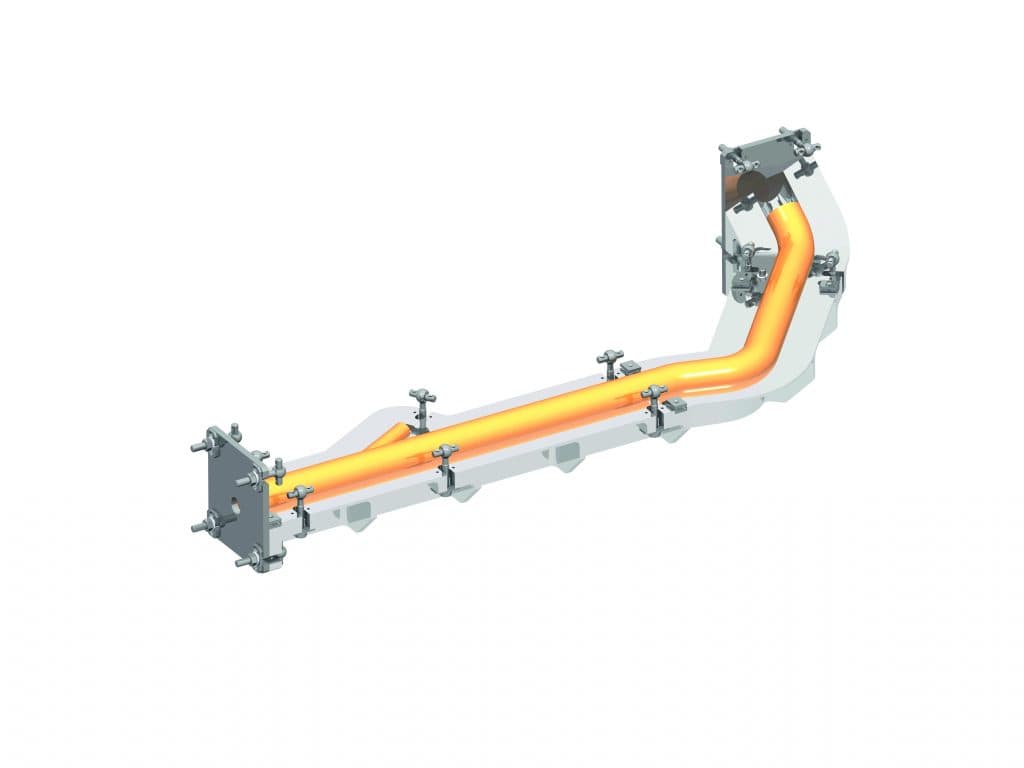

- The geometric definition of your parts in composites,

- The tools and molds,

- Use of complex assemblies,

- Functional dimensioning,

- To optimize the design, we check their mechanical behaviour thanks to fem calculation.

We use structural calculations to optimize part design.

A good knowledge of processes such as :

- Wet and vacuum lamination,

- Prepreg in autoclave,

- RTM injection, infusion,

- Compression molding, TP composites stamping...

This enables us to design the appropriate tooling.

Process simulation (RTM and infusion in particular) is an optimization phase that complements tool design.

Structural calculation

Finite element analysis is used to assess the mechanical strength of part in its context of use. In case, we intervene on the shape of part, its "composite" constitution (quality, quantity, etc).

The main benefits are as follows :

In the upstream design phase :

- Pre-dimension the parts to be subjected to your load cases,

- Determine the type, quantity and location of composites to be used,

- Obtain a provisional mass balance,

- Pre-calculate the cost of part...

Subsequently :

- Optimize composites consitution,

- Lighten parts,

- Assess structural failure...